Ethane Cracker Process Flow Diagram

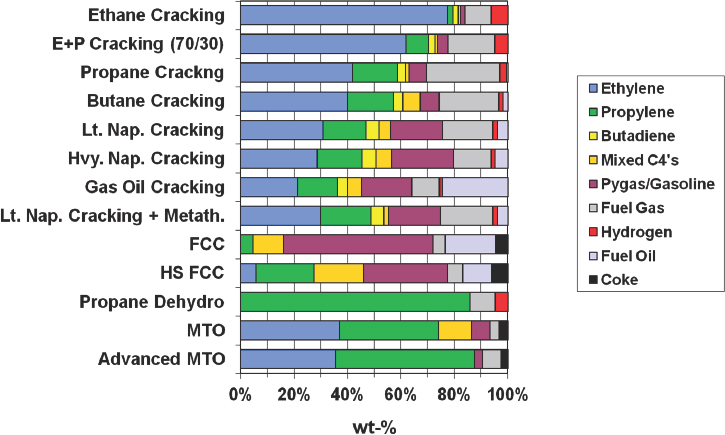

The proposed design consists of six main sections. Typical process features of an ethyl ene process are short residence time in the furnace high selectivity feed stock flexibility operational reliabil ity and safety easy start up and energy efficiency.

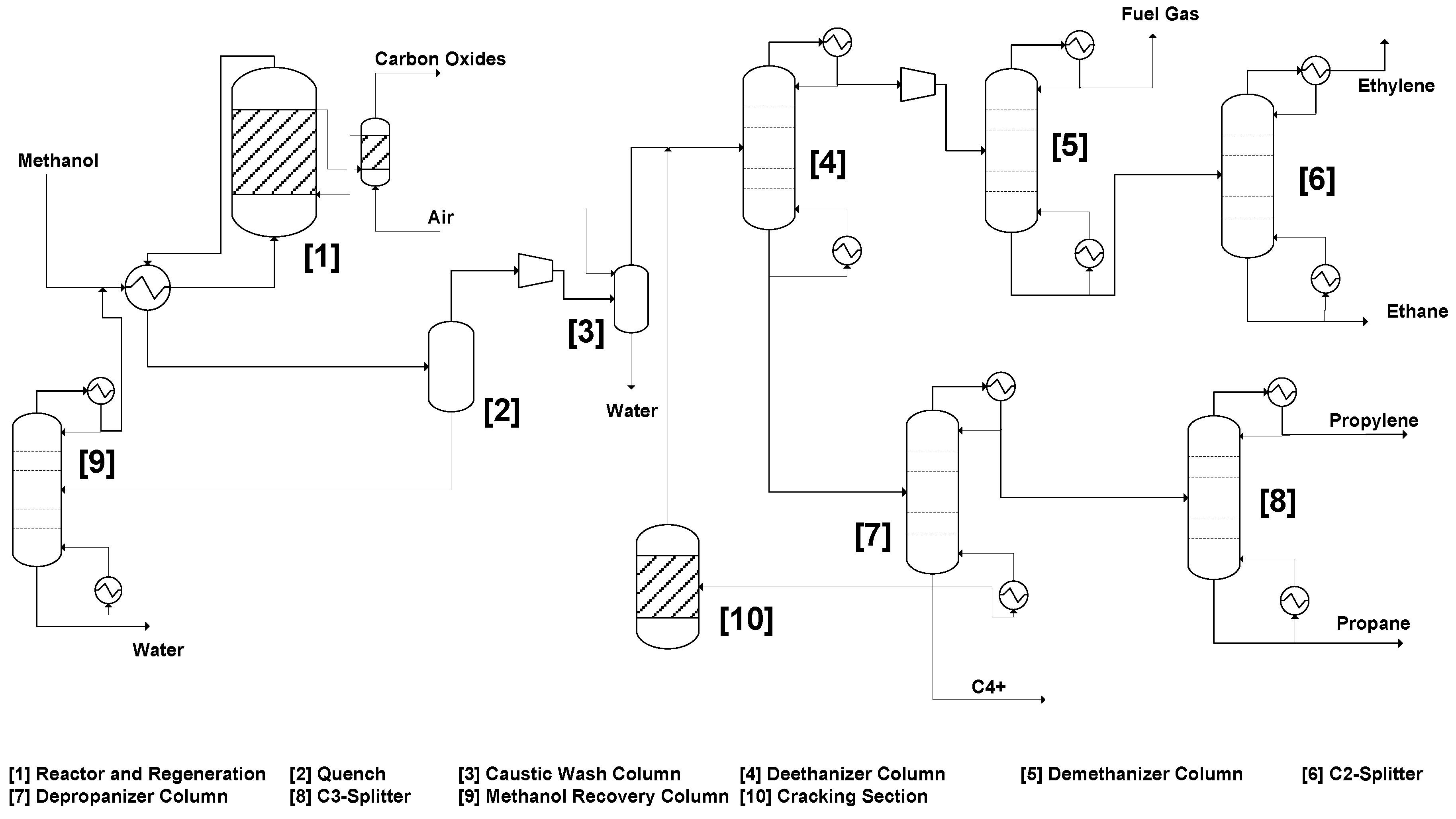

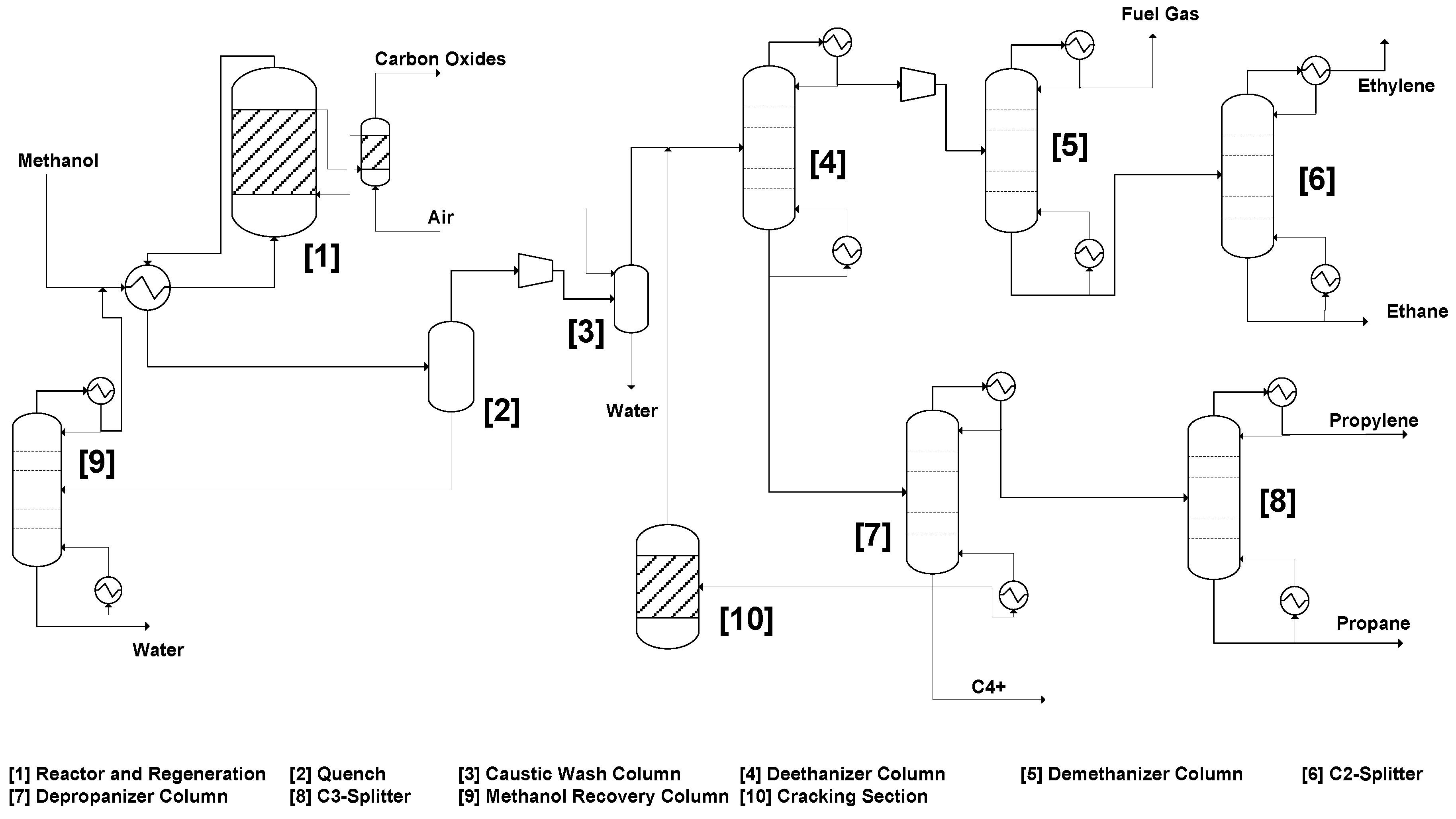

Process Flow Diagram Methanol To Propylene Process 17 Download

Process Flow Diagram Methanol To Propylene Process 17 Download

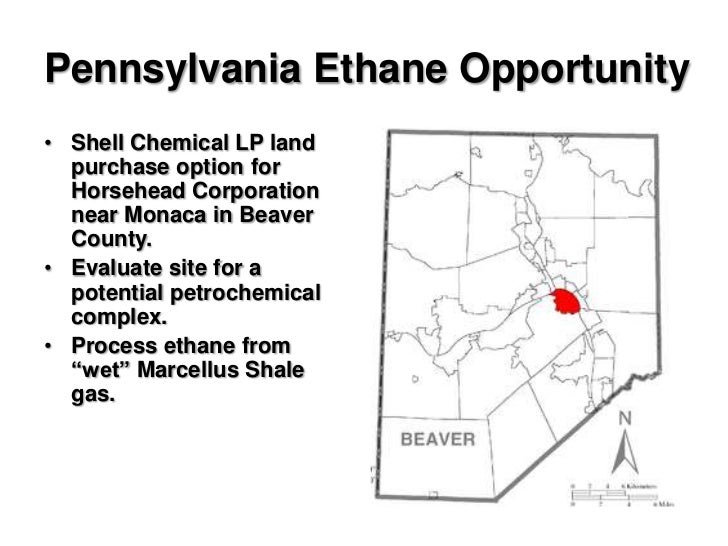

The new facilities will process ethane to produce ethylene and other products.

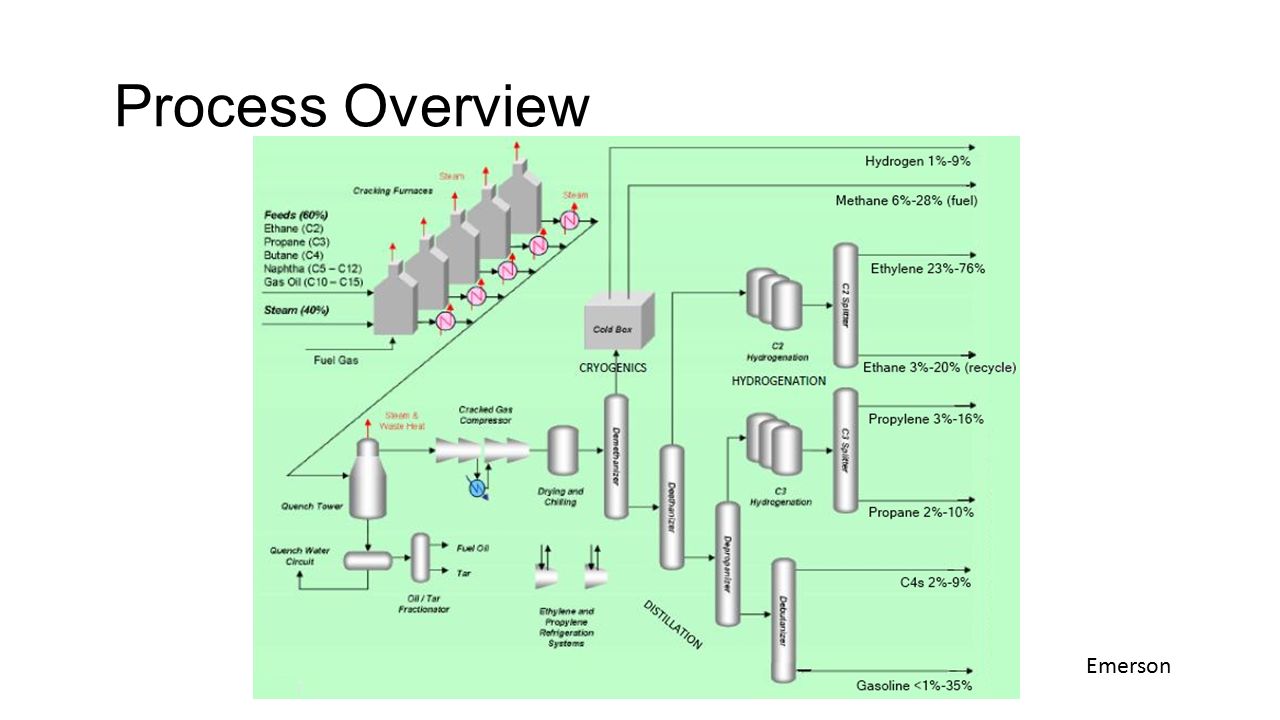

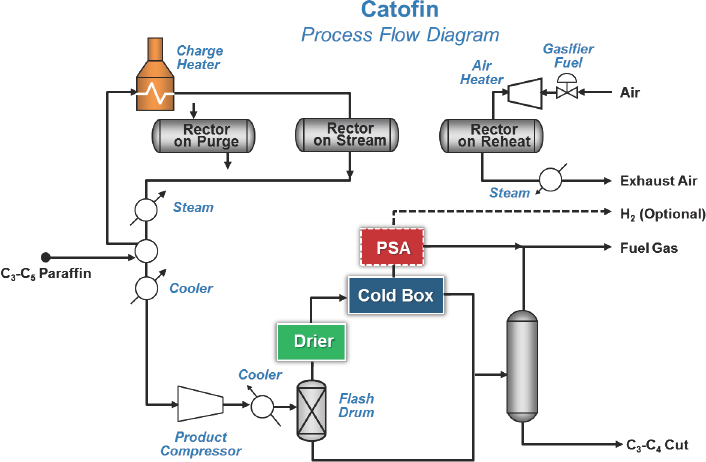

Ethane cracker process flow diagram. Normal operation assumes five furnaces continuous operation and one furnace on hot stand by or decoking operations. Cracking is accomplished by heating ethane to greater than 800c 1500f in the cracker furnace. Flow diagram for pyrolysis of napththa is given in figure m vii 21.

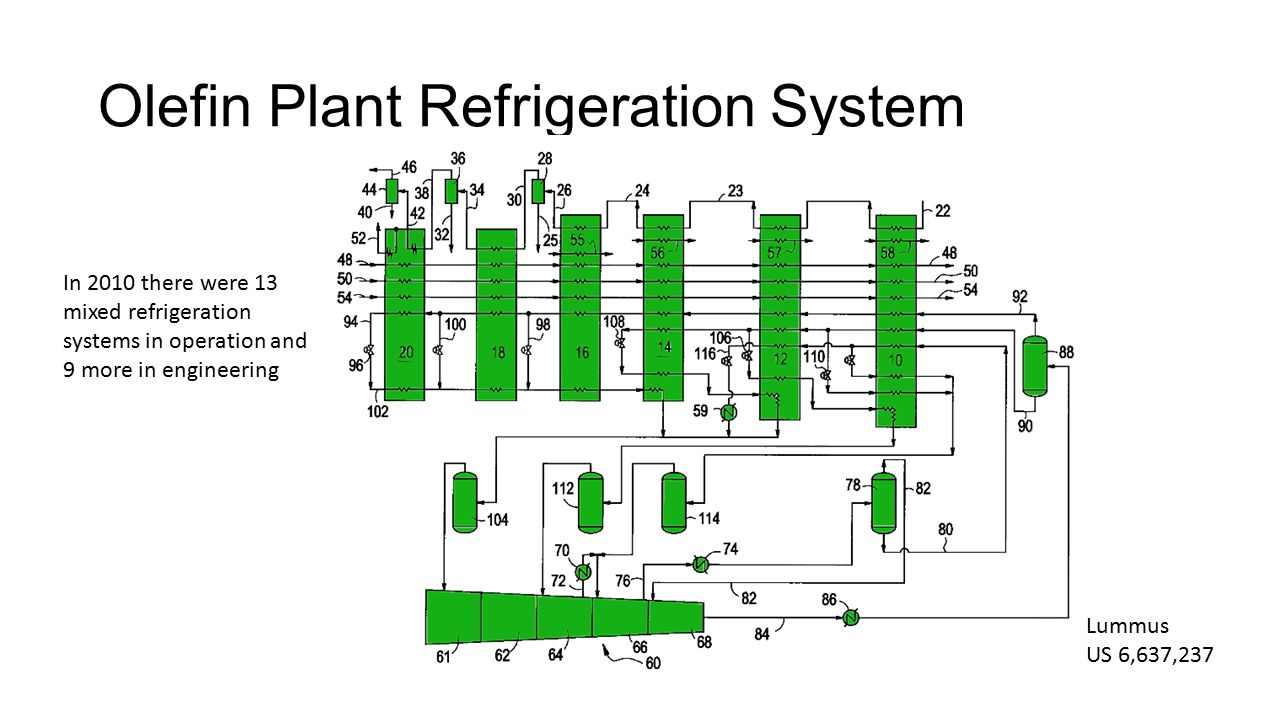

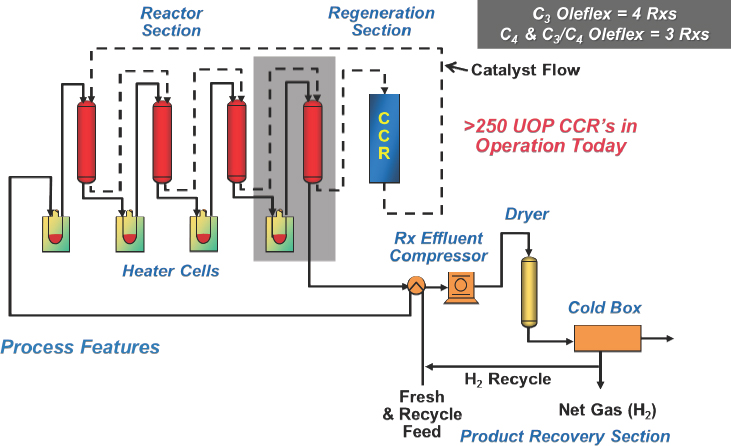

Various steps involved in the pyrolysis of naphtha and separation of the products are discussed below. Initially an ethane propane mixture is fed to furnaces in which under high severity conditions it is cracked forming ethylene propylene and other byproducts. Acid gas removal dehydration fractionation train hydrogenation reactor an ethylene splitter and steam cracking refer to appendix b for the process flow diagram.

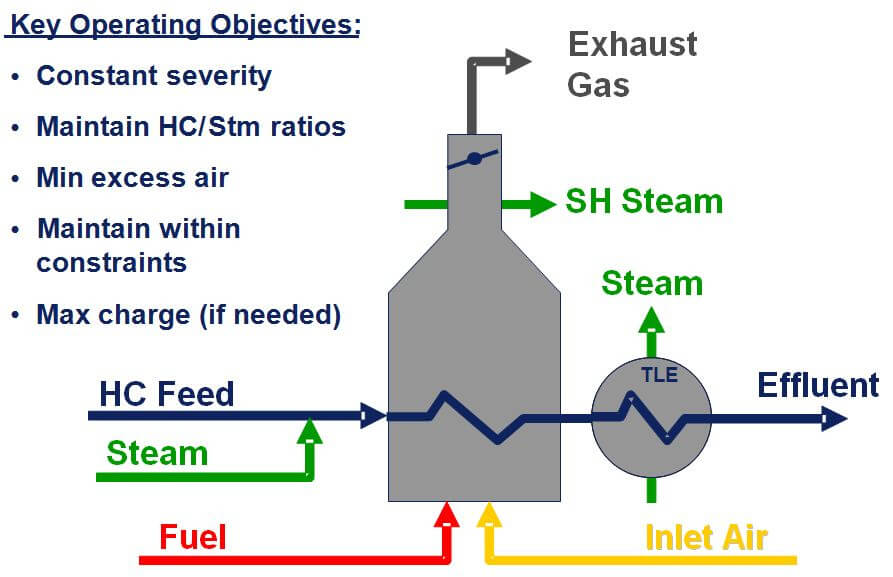

This process diagram shows an ethylene production process via the cracking of an ethane propane mixture cracking and quenching. Steam cracker 170 mw heat duty modeled as 2 100mw separate pyrolysis furnaces each furnace 100 mw capacity operates at 80 capacity. Carbon dioxide must first be removed from the inlet shale gas in the acid gas removal section.

Process analytics is a key issue for process control by online monitor ing the various process streams in ethylene and propylene production. The proposed project will contain typical process equipment. Linde 713 873 1708.

A process flow sequence is shown on the block flow diagram figure 2 1. The ethane crackers fuel consists of a mixture of recycled tail gas hydrogen rich and natural gas methane with a heating value of 523 btuscf. The cracking process involves breaking up the carbon and hydrogen molecules and rearranging them.

In case of gas cracking separation of ethane and propane from natural gas is involved. Advances in ethane cracking. Image courtesy of cbi in ethane cracking fresh feedstock and recycled ethane are thermally cracked in the presence of steam in a bank of pyrolysis furnaces.

Hot section it consists of convection zone and radiant zone. The ethane recovered from the process is recycled to the feed stream. Process flow diagram for ethane cracking.

Ethane must be cracked to make ethylene 26.

Crude Oil To Chemicals Light Olefins From Crude Oil

Advances In Ethane Cracking Ppt Download

Advances In Ethane Cracking Ppt Download

The Propylene Gap How Can It Be Filled American Chemical Society

The Propylene Gap How Can It Be Filled American Chemical Society

New Catalytic Process For Production Of Olefins Oil Gas Portal

Efficiently Cracking Hydrocarbons In Ethylene Furnaces Emerson

Efficiently Cracking Hydrocarbons In Ethylene Furnaces Emerson

Shell S Pennsylvania Ethane Cracker To Take Shape Over Next Year

Shell S Pennsylvania Ethane Cracker To Take Shape Over Next Year

Cracking And Related Refinery Processes

Process Flow Diagram For Ethane Crackers Areas In Red Are Not

Process Flow Diagram For Ethane Crackers Areas In Red Are Not

Cracking And Related Refinery Processes

Nptel Chemical Engineering Petroleum Refinery Engineering

Nptel Chemical Engineering Petroleum Refinery Engineering

Non Catalytic Ethane Cracking Using Concentrated Solar Energy

Non Catalytic Ethane Cracking Using Concentrated Solar Energy

Advances In Ethane Cracking Ppt Download

Advances In Ethane Cracking Ppt Download

Ethylene Process By Technip Process Engineering

Shale Gas To Ethylene G2 Processdesign

Shale Gas To Ethylene G2 Processdesign

Fcc Flow Diagram Wiring Diagram Document Guide

Fcc Flow Diagram Wiring Diagram Document Guide

4 Catalytic Conversion Of Light Alkanes The Changing Landscape Of

4 Catalytic Conversion Of Light Alkanes The Changing Landscape Of

4 Catalytic Conversion Of Light Alkanes The Changing Landscape Of

4 Catalytic Conversion Of Light Alkanes The Changing Landscape Of

Process Flow Diagram Methanol To Olefins Process 13 14 Download

Process Flow Diagram Methanol To Olefins Process 13 14 Download

Schematic Of Ethane Steam Cracking Furnace Download Scientific Diagram

Schematic Of Ethane Steam Cracking Furnace Download Scientific Diagram

Process Economics And Safety Considerations For The Oxidative

Flowsheet Of Ethane Steam Cracking Furnace In Aspen Plusdynamic

Flowsheet Of Ethane Steam Cracking Furnace In Aspen Plusdynamic

4 Catalytic Conversion Of Light Alkanes The Changing Landscape Of

4 Catalytic Conversion Of Light Alkanes The Changing Landscape Of

Typical Flow Diagram For A Naphtha Steam Cracker Figure Was Drawn

Typical Flow Diagram For A Naphtha Steam Cracker Figure Was Drawn

Shale Gas To Ethylene G1 Processdesign

Shale Gas To Ethylene G1 Processdesign

Processes Free Full Text A Techno Economic Comparison Between

Processes Free Full Text A Techno Economic Comparison Between

0 Response to "Ethane Cracker Process Flow Diagram"

Post a Comment